Bending and Gluing the C-Bout Ribs

Bending

To bend the ribs to match the mould I used another homemade contraption. All credit for the idea goes to Sam Harper. It is definitely not a beautiful machine but I already had a heat gun and the piping was around $15.

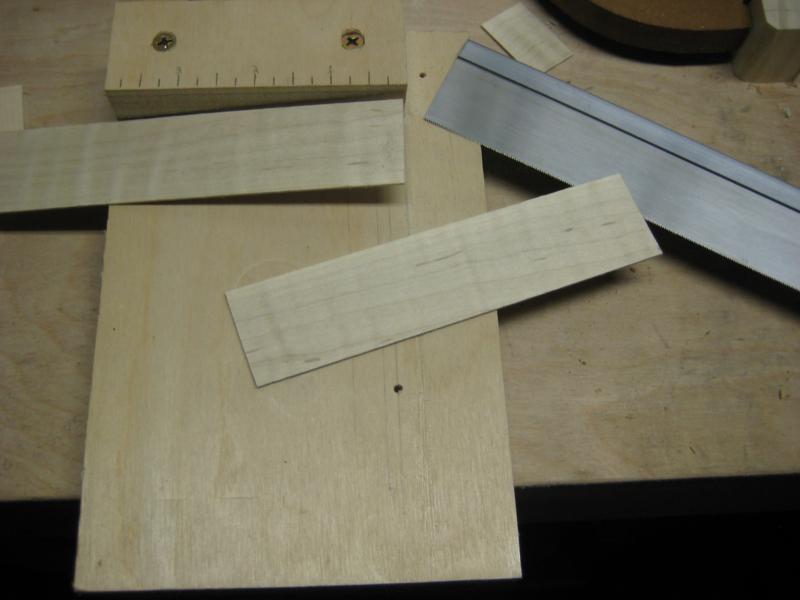

First, I bend the c-bouts or middle ribs. Before bending I cut down the ribs to size using a bench hook and a 32TPI saw.

First, I bend the c-bouts or middle ribs. Before bending I cut down the ribs to size using a bench hook and a 32TPI saw.

To make sure the ends are square I flipped over the bench hook and used it as mini shooting plane. To square the end I used some sandpaper wrapped around a block of wood.

To make sure the ends are square I flipped over the bench hook and used it as mini shooting plane. To square the end I used some sandpaper wrapped around a block of wood.

After the iron gets nice and hot I used a bending strap to support the ribs while they are bent.

After the iron gets nice and hot I used a bending strap to support the ribs while they are bent.

I found the bending iron to work well for the tight curves, but for the more gentle curves it was quite difficult to bend the ribs in a smooth fashion. Making corrections was also difficult since there was no flat area to work with. At the end of the day I was disappointed with my c-bouts, so overnight I left them lightly clamped in the mold and pondered buying a real bending iron. The next day when I checked them they had actually seemed to conform much better to the mold and blocks. Either they did bend a little, I wasn’t feeling as anal as usual, or the ghost of some great maker lent me a hand during the night. Next time I’ll either fork over the cash for a real bending iron or I may try cold bending with forms.

I found the bending iron to work well for the tight curves, but for the more gentle curves it was quite difficult to bend the ribs in a smooth fashion. Making corrections was also difficult since there was no flat area to work with. At the end of the day I was disappointed with my c-bouts, so overnight I left them lightly clamped in the mold and pondered buying a real bending iron. The next day when I checked them they had actually seemed to conform much better to the mold and blocks. Either they did bend a little, I wasn’t feeling as anal as usual, or the ghost of some great maker lent me a hand during the night. Next time I’ll either fork over the cash for a real bending iron or I may try cold bending with forms.

Gluing

Before gluing the ribs I put the spacer screws back in the bottom to lift the mold very slightly off the table. I used hide glue to glue the c-bouts to the blocks. To do this I had to practice getting the clamps on in quick manner since the hide glue gels quickly. This is the first clamping method recommend by Strobel. It seemed clunky as the c-clamps would run into each other while tightening. Not much force is needed so cutting off the ends of the clamps may make it easier, or there’s a thousand other ways to clamp the c-bouts. Note to self: be more diligent in cleaning up the excess hide glue before it drys, scraping hard hide glue is no fun.